I can’t believe that it’s’ been almost 4 weeks since I last posted to the blog.

Building during the Christmas holiday threw some delivery set-backs into the mix that we hadn’t counted on. As of right now, the barn is about 98% done. The builders have to put up the gutter on the left side and the metal above the greenhouse on the shared wall (where the greenhouse connects to the side of the barn). We put up the last of the insulated panels on the inside but have to finish insulating the ceiling next spring (after the electrician finishes his work).

The electrician was delayed in finishing the job because the builder had not put the metal on the barn yet and he needed the metal in order to mount his electrical boxes to it. I’m not sure if it’s typical of all contractors to promise you a certain completion date and then they don’t hit it…again and again and again. It was very frustrating. The builder felt sure he’d be done by Christmas…now it’s looking like it will be January 9th for everything to be finished.

Our Amish builder built the wooden barn doors for us and we love them. Come spring we’ll get a coat of paint on them. All of the electrical is done for the barn. Before he put the breaker box inside the barn, we had already made the decision to go from a 100 amp service to a 200 amp service. Due to some of the amperages of current and future items we want, it only made sense to do it now before the whole thing was installed. What that did affect though was getting an excavator to come back out and dig another trench from the pole to the barn. I think the increase in cost was minimal in comparison to having it done down the road, when everything would have to be changed out. I knew the breaker boxes are a different size (when going from 100 amp to 200 amp) but boy, have the 200 amp boxes gotten large. Everything goes up in size…the mast head at the top of the electric pole, the wire size coming in from the pole (it almost triples in size), and a different meter on the pole. It will be worth it to have the capability to add more circuits and be able to expand our business.

Greenhouse Construction:

The greenhouse construction has progressed very quickly, once the rafters were completed by the builder. He encountered some problems getting his workshop warm enough to cure the epoxy but once he got all of that worked out, he built the rafters in about a week. A week-long visit from family delayed them getting back to work so the original completion date of Christmas came and went.

The rafters are a unique aspect of the greenhouse. They need to be arched so that the gentle wrap of the poly plastic over the frame will not allow the plastic to flap in the wind and stress the plastic. Our rafters (and the whole design of the greenhouse) came from plans we purchased from Friendly Aquaponics .

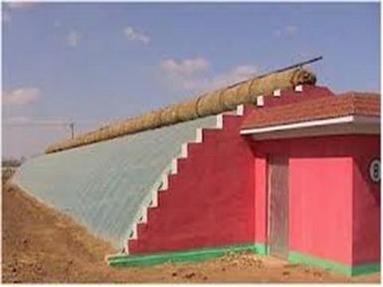

This greenhouse is designed after Chinese-style greenhouses that were constructed thousands of years ago.

The important components that make this style of greenhouse so different from typical greenhouses is that three of the walls are insulated (north, east and west walls). On the Chinese style greenhouse shown above you can see the rolled mat on the roof, which is a thermal blanket that is rolled down over the face of the greenhouse at night to keep the heat in.

For our greenhouse we decided to use SIP’s (structural insulated panels) that we had left from insulating the barn and we used those to insulate the walls of the greenhouse. Between the Prodex and SIP’s we have an R-value of R-37 in the east, west and north walls of the greenhouse. There are no fossil fuel heating sources used in the greenhouse. Since our growing takes place in troughs, filled with water, we have a tremendous amount of thermal mass that will be in the greenhouse. Contrary to common growing practices in greenhouses, the important element is the water temperature, rather than the air temperature. The water in the tank that will house the fish will kept at a constant 72 degrees and this water will circulate through the troughs, where the veggies will be growing. Maintaining that 72 degrees temperature in the troughs is crucial. We insulated the floor of the greenhouse with Prodex, which will help us maintain and hold that temperature in the trough. We’ve also put Prodex around the tank that will hold the fish. I purchased two 300 gallon IBC totes. You have to be really careful where you get totes because you don’t want to buy something that had toxic chemicals stored in them or you’re fish won’t be around for long.

We had to have an excavator come in to put some fill inside the greenhouse to bring the floor up to where it should be. There was almost a 10” difference in drop from the front of the building to the back. Since our buildings are sitting at the base of a hillside, it made for a challenging site orientation for the buildings. Gravel was put in first and then 4” of sand on top. Today we put down the organic diatomaceous earth and citric acid, before putting down the layers of plastic and weed mat. The citric acid is a natural weed killer and the diatomaceous earth will kill any ants if they should try to come up under the greenhouse. When the troughs are built and the form stakes are driven into the ground, the DE will go with it and provide pest protection around these penetrations. On top of the DE and citric acid we put 6 mil black construction plastic, then a layer of Prodex and then geotextile fabric. All of these layers should provide a weed free, bug free (at least from creepy crawly things coming under the greenhouse) and insulated greenhouse.

At the end of the week, the plastic will go on, using wiggle wires and track (more on that next time). The metal has to go up on the ends of the greenhouse, a door installed on each end, solar fans mounted and gutter put on the barn. Friday should see most of this task list completed. The metal will have to wait a week since it won’t come in till next week. Sad for us because we have to leave on Sunday to go to Texas for a few months to complete some work assignments. Once we get back I will start building the troughs, the electrician will come back to put receptacles in the greenhouse and we’ll get veggies started. It’s been a super busy couple of months, stressful at times, but we can see the light at the end of the tunnel. Good times ahead…..stay tuned for what we have in store.

No comments:

Post a Comment